TL; DR: Keeping your gas detection equipment accurate and reliable isn’t just about ticking boxes. It’s about regular calibration, quick bump tests, careful storage, and making sure your team knows how to use the devices properly. Skipping these basics puts your people, operations, and compliance at risk. A few simple habits can prevent costly downtime or worse.

Key Takeaways:

- Calibrate regularly with a two-point method and don’t rely on factory settings

- Always bump test before use, especially in high-risk or rugged environments

- Store detectors in clean, stable conditions away from heat, moisture, and fumes

- Train your team on use, maintenance, and alarm responses to avoid misuse

Gas detection systems are not just a compliance formality. In high-risk settings, they serve as the front-line safeguard against toxic or explosive gases that can cause serious harm.

Even the most advanced detectors won’t help if they’re neglected.

We’ll go through practical, often-overlooked methods to ensure your gas detection equipment stays reliable and accurate.

This goes beyond meeting regulations; it’s about protecting lives, keeping your operations running smoothly, and making sure safety isn’t left to chance.

If It’s Not Calibrated, It’s Not Working

Don’t Trust the Factory Settings Forever

Gas detectors often arrive pre-calibrated and ready for use, but their accuracy doesn’t last indefinitely. Over time, sensors can wear out or drift, especially when exposed to temperature changes, humidity, or airborne contaminants. Calibration is the only way to ensure the readings you rely on remain dependable.

Pro tip: Relying on an annual calibration schedule may not be enough. In environments where sensors are under constant stress, such as chemical plants or outdoor sites, monthly or even weekly checks may be necessary to avoid false readings or undetected hazards.

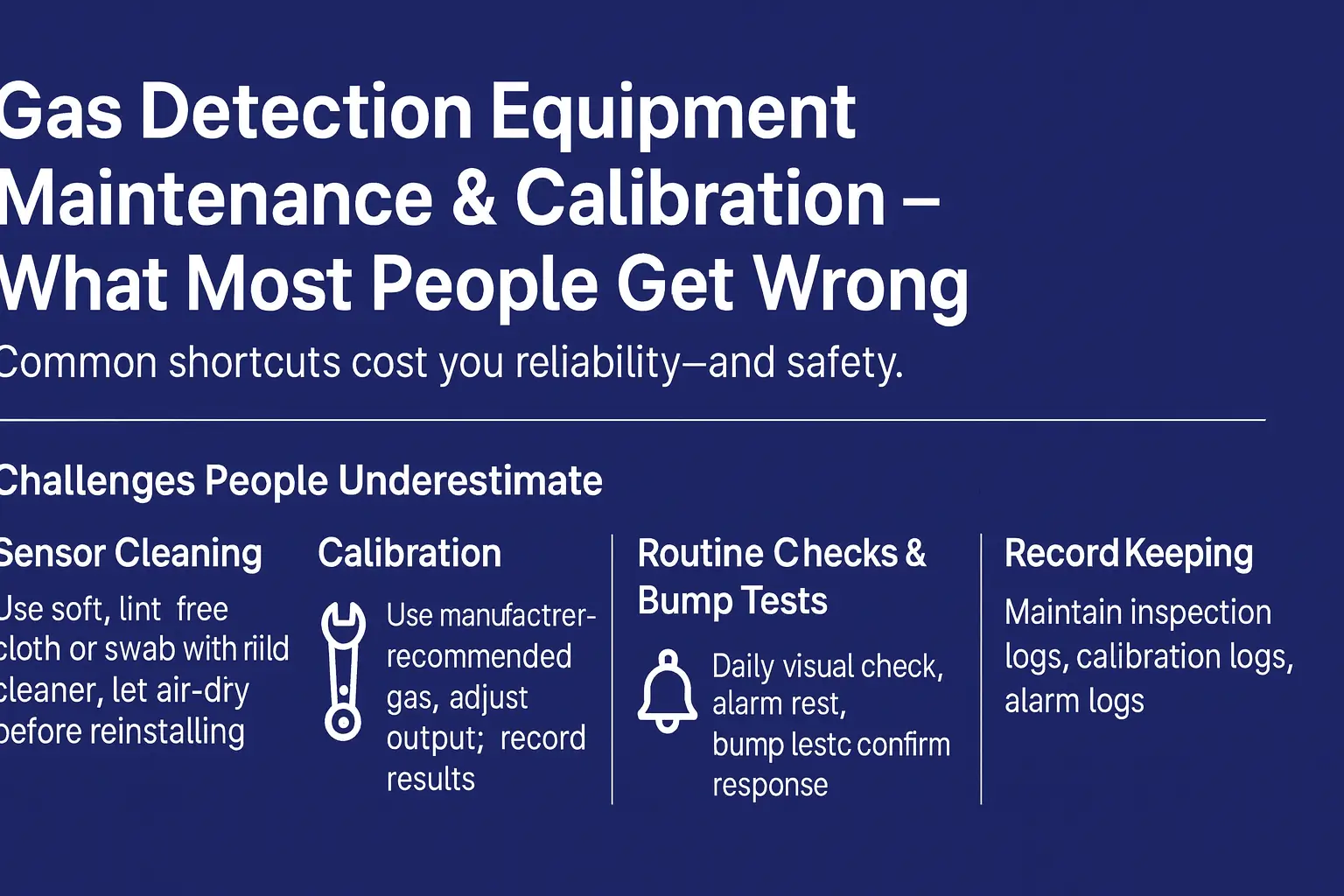

Two-Point Calibration Isn’t Overkill; It’s What Professionals Use

You might come across the idea that single-point calibration is sufficient, but that’s a shortcut that can lead to inaccurate readings. A proper two-point calibration involves checking the sensor at both zero and a known concentration of gas.

This process helps confirm that the detector is giving reliable readings throughout its entire operating range, not just at a single data point.

Bump Testing: The Simple Check That Could Save a Life

Bump tests are quick and affordable, yet often overlooked. They involve exposing your gas detector to a known gas to make sure it responds correctly. You’re not adjusting the calibration here; you’re just confirming the sensor is still working as it should before putting it into service.

When to bump test:

- Before the start of each shift in high-risk environments where gas exposure is possible

- Immediately after the device has been dropped or physically impacted in any way

- When the detector has been unused or stored for a prolonged period, especially in poor conditions

If you skip this step, you’re relying on a device you hope is working instead of knowing for sure. It’s a small action that could make all the difference.

Don’t Clean with Whatever’s Nearby

Using harsh solvents or common household cleaners might seem convenient, but they can damage sensitive sensors or leave behind residues that interfere with accuracy. Even a small amount of leftover chemical can throw off readings and compromise your system’s reliability.

Use Manufacturer-Approved Wipes or Cloths

Stick with soft, lint-free cloths that won’t leave residue behind. If your device has stubborn dirt or buildup, refer to the manual for approved cleaning methods. And if there’s no specific cleaner mentioned, it’s best to avoid using anything else.

Taking chances with unapproved substances could damage the sensors and affect the reliability of your readings.

Pay Attention to Where You Store Your Devices

Leaving your gas detectors in the wrong environment when they’re not in use can quietly ruin their accuracy. High temperatures, excess humidity, and lingering chemicals can all cause sensors to degrade faster than expected.

What to Do:

- Store devices in a clean, dry space with stable temperatures

- Use designated cabinets or enclosures recommended for electronic safety gear

- Make sure the storage area is away from production zones or chemical storage

What to Avoid:

- Don’t place detectors near running engines, machinery, or exhaust outlets

- Don’t store them in areas exposed to cleaning agents or chemical fumes

- Don’t leave them near windows or vents where heat and moisture can build up

If a detector has been sitting for months in a poor environment, there’s a good chance it won’t work properly when you need it most.

If you’re noticing more false alarms or inconsistent readings lately, it may not just be a maintenance issue. Your equipment might be overdue for an upgrade.

Check out the signs your gas detectors need replacing before problems escalate.

Don’t Let Poor Record-Keeping Come Back to Bite You

If you don’t keep a record, it’s hard to prove that maintenance was done properly. When something goes wrong, the responsibility often lands on whoever last handled the equipment. Keeping accurate logs isn’t just a formality. It’s a practical step that helps protect you and your team.

Your records should include key details like calibration and bump test dates, any component replacements, and notes about error messages or unusual behaviour. It doesn’t need to be complicated, just reliable.

Digital logs are especially useful because they help you stay organised and save time during inspections or audits. They show that your team is on top of things and taking safety seriously.

It’s Not Just Maintenance; It’s About Knowing What to Do

Many companies invest in high-end gas detectors but overlook a crucial step: making sure their team knows how to use them correctly.

It’s easy to assume the devices are straightforward, but without proper training, even reliable equipment can give poor or misleading results.

Before jumping into training, it’s helpful to understand how these devices work. If your team needs a refresher, here’s a quick read on what gas detectors are and how they work.

What Your Team Should Know:

- How to check the detector before each use, including basic function tests

- What the alarms mean and the immediate steps to take

- How to recognise early signs of sensor failure or irregularities

- The right way to clean, store, and care for the unit to maintain its performance

Training doesn’t need to be overly technical, but it should be practical and repeatable. Once your team is trained, keeping a simple log helps reinforce accountability and supports both internal standards and regulatory compliance.

Why Choose Minerva?

At Minerva Intra, we understand what’s really at stake when gas detection equipment fails. We don’t just sell you a device and walk away. We provide solutions that keep working when it counts.

We offer:

- Maintenance training for your staff

- Calibration services for all major brands

- Advice tailored to your work environment

We believe in giving you the tools, support, and know-how to protect what matters most: your people.

If you’re not sure your current system is up to standard, let’s talk. We’re here to help you stay compliant, confident, and ready.

For more details on the gas detection and environmental monitoring systems we provide, visit our Gas & Flame Detection Solutions page.

Ready to Strengthen Your Gas Detection System?

Whether you need help with calibration, team training, or evaluating your current setup, we’re here to support you. Don’t wait for an incident to highlight a weak point in your safety plan.

Contact Minerva Intra today to speak with our team and find a tailored solution that fits your operation.