TL;DR: Gas detection systems are getting smarter, faster, and easier to manage. With AI, cloud monitoring, and wireless wearables, industries are improving safety and staying compliant without the usual complexity.

Key Takeaways:

- Gas detectors today are smarter, lighter, and better connected than ever.

- Cloud and AI tech are helping teams prevent issues before they escalate.

- Regulations are tougher, so automated reporting and calibration features save time and stress.

- Integrated safety systems give quicker, more coordinated responses in emergencies.

Why Everyone’s Rethinking Their Gas Detection Systems

Gas leaks and hazardous gases used to be seen as issues only major industrial sites had to deal with. But that view is quickly changing. With a sharper focus on workplace safety, stricter environmental laws, and better access to advanced technology, gas detection systems are evolving in ways that were hard to imagine a decade ago.

They’re not just getting faster; they’re getting smarter and more intuitive. And that matters because when something goes wrong, you don’t always get a second chance.

In industries where timing is everything, even a short delay can cost lives or result in severe financial losses.

So, what exactly is shifting in this space?

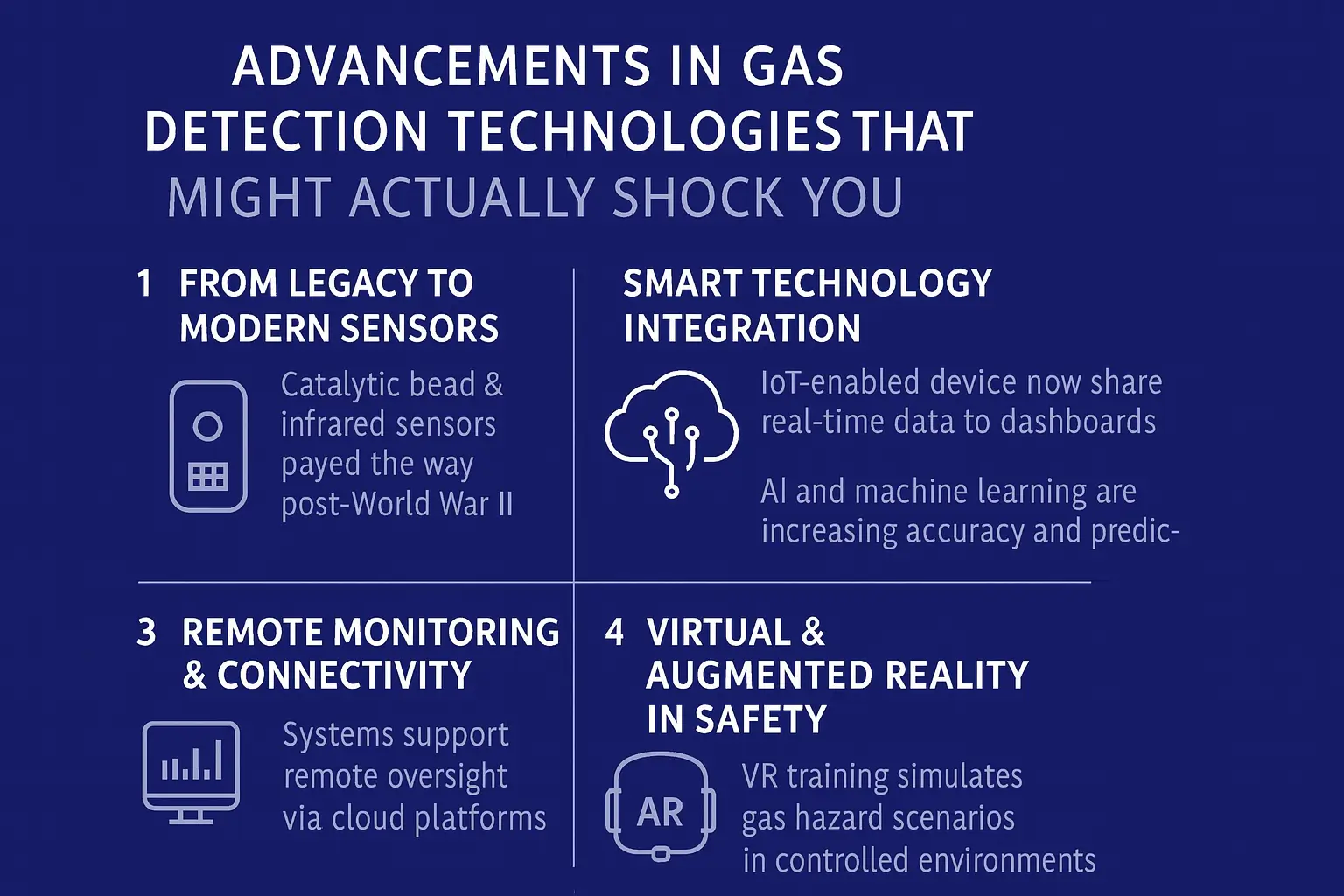

Smarter Sensors Are Replacing Traditional Setups

The Death of One-Trick Detectors

Old-school gas detectors were built to do one job: detect a specific gas and sound an alarm. That was fine for its time. But in today’s high-risk environments, we need multitaskers.

Modern sensors are now designed to detect multiple gases simultaneously, giving safety teams a much clearer picture of what they’re dealing with in real time. These advanced systems use:

- Photoionisation Detectors (PIDs): Ideal for detecting volatile organic compounds (VOCs) at low concentrations.

- Non-Dispersive Infrared (NDIR) Sensors: Best suited for identifying gases like carbon dioxide, methane, and other hydrocarbons.

By combining multiple detection methods, modern systems can monitor a wide range of hazardous compounds with a high degree of accuracy; often with faster response times and lower false alarm rates.

AI Integration: Not the Future; Already Here

Artificial intelligence is transforming how data from sensors is used. New gas detection technologies don’t just detect; they analyse. Machine learning algorithms are being used to predict leak patterns, minimise false alarms, and provide real-time diagnostics to site operators.

Some systems are even self-calibrating, cutting maintenance time drastically.

If you’re exploring ways to improve operational efficiency while enhancing safety, this article on The Advantages of Remote Monitoring dives deeper into how remote access and smart systems are changing the game in industrial environments.

Wireless and Wearable Tech Is Going Mainstream

Goodbye to Wires, Hello to Freedom

Wired systems have long served their purpose, but they can be limiting especially in busy, ever-changing industrial settings. Running cables across large areas or complex layouts not only takes time but can be a logistical headache.

That’s why more and more companies are turning to wireless gas detectors. They’re quicker to install, easier to move around as site layouts evolve, and offer more flexibility in how they’re deployed.

Personal Gas Detectors That Workers Actually Want to Wear

There’s also been a noticeable shift in how gas detection fits into the daily routine of workers. Gone are the days of bulky gear that gets in the way or feels like a burden. Today’s personal detectors are sleek, lightweight, and designed to be worn all day without discomfort.

Clipped onto a uniform or attached to a belt, they feed real-time exposure data to supervisors and safety managers, giving everyone a clearer view of conditions on the ground.

Cloud-Connected Monitoring Is Becoming Standard

Data That Works When You’re Not Watching

Cloud-based platforms are changing how businesses manage gas detection across their sites. Instead of needing someone physically present to check data or maintain logs, everything can now be monitored from a centralised dashboard.

Whether it’s a single factory floor or multiple sites spread across the region, teams have round-the-clock visibility. This translates into smoother compliance processes, more accurate data records, and fewer missed issues during safety audits.

Remote Response, Real Results

Emergencies often strike when no one expects them, and those first few moments are crucial. That’s exactly where cloud-connected systems prove their value. These platforms allow safety teams to act quickly, even if they’re working remotely. The ability to respond without delay can drastically change the outcome of an incident.

With just a few clicks, teams can:

- Trigger on-site alarms to alert nearby personnel

- Initiate shutdown protocols to prevent escalation

- Notify emergency responders with precise, location-based information

For businesses considering or updating their detection systems, it’s also worth reviewing this practical guide: Flammable Mistakes: How to Avoid the Wrong Gas & Flame Detection Setup.

Integration With Building Management and Automation Systems

No More Standalone Safety

Gas detection is no longer operating in isolation. The latest systems are being linked with building and process management platforms to create a more responsive safety network.

Now, a gas leak can automatically activate ventilation, shut down equipment, or even start evacuation procedures based on the severity of the event. The response becomes smarter, faster, and more precise.

One System to Rule Them All

In the past, fire detection, HVAC control, and gas monitoring often ran on separate systems, each doing its own thing. But that siloed approach can cause delays when quick, coordinated action is needed. Integrated platforms solve this by connecting all those components into one cohesive setup.

The result? Safer environments, quicker decision-making, and less room for error when it matters most.

Compliance Is Getting Stricter, and Tech Is Stepping Up

Regulations Aren’t Slowing Down

Across industries, safety and environmental regulations are becoming more demanding. Whether driven by government mandates or industry best practices, the pressure to meet higher standards is real.

This is motivating more companies to move beyond the basics and invest in detection systems that are accurate, smarter, and more proactive.

Proof in the Numbers

One of the most valuable upgrades in modern gas detection systems is their ability to deliver detailed, time-stamped reports automatically. These systems now capture and organise essential data in real time. Key logs include:

- Exposure levels over time

- Scheduled and completed maintenance checks

- Response times to alarms or incidents

The ability to access this data quickly and clearly is a big help during safety audits and compliance checks. More importantly, it gives teams and regulators confidence that risks are being managed with care and nothing is being overlooked.

The Quiet Revolution in Calibration and Maintenance

Auto-Calibration: A Lifesaver

Older gas detection systems often needed technicians to perform manual calibration checks on a regular basis. This routine was not only time-consuming but also added ongoing labour costs.

The latest generation of detectors is changing that by including auto-calibration features.

- Self-calibrates without manual checks

- Maintains accuracy and reliability

- Alerts teams early if something’s wrong

Predictive Maintenance

Rather than reacting to problems after they occur, predictive maintenance helps teams get ahead of them. New gas detection systems can track wear and performance trends and notify maintenance teams early when components are beginning to degrade.

This reduces surprise failures, lowers repair costs, and helps avoid unplanned downtime that can disrupt operations and compromise safety.

Why Choose Minerva

At Minerva Intra, we believe that safety shouldn’t be an afterthought. It should be a built-in part of every worksite, woven into the daily routine of your operations.

That’s why we focus on delivering dependable, future-ready gas detection and environmental monitoring systems tailored for real-world industrial demands.

We’ve supported businesses in sectors like oil and gas, petrochemical, marine, and manufacturing, helping them comply with evolving safety standards and operate with peace of mind.

For a closer look at the full range of our gas detection, flame detection, and environmental monitoring solutions, visit our dedicated service page: Gas & Flame Detection and Environmental Monitoring.

Talk to Us Before You Make Your Next Gas Detection Decision

Ready to modernise your safety systems with technology that keeps up with your needs? Whether you’re upgrading or building from scratch, we can help you plan it right.

Contact us today to book a consultation with our gas detection specialists. Let’s keep your team safe, smart, and compliant.