TL;DR: Custom gas detection solutions provide targeted protection across different industries by addressing specific risks, environments, and gases. They improve safety, reduce downtime, support compliance, and give workers and businesses greater confidence that hazards are being managed effectively.

Key Takeaways:

- One-size-fits-all gas detection systems often miss critical hazards unique to each industry

- Tailored systems improve worker protection, compliance, and operational continuity

- Preventive maintenance extends system reliability and ensures long-term safety

- Investing in customised solutions builds trust with workers, regulators, and surrounding communities

The Hidden Dangers No Industry Wants to Talk About

When it comes to safety, too many industries rely on one-size-fits-all gas detection systems that don’t quite match their unique risks.

The truth is, gases behave differently depending on the environment, and the wrong detection setup could mean the difference between safety and disaster.

That’s why custom gas detection solutions are no longer a luxury; they’re a necessity.

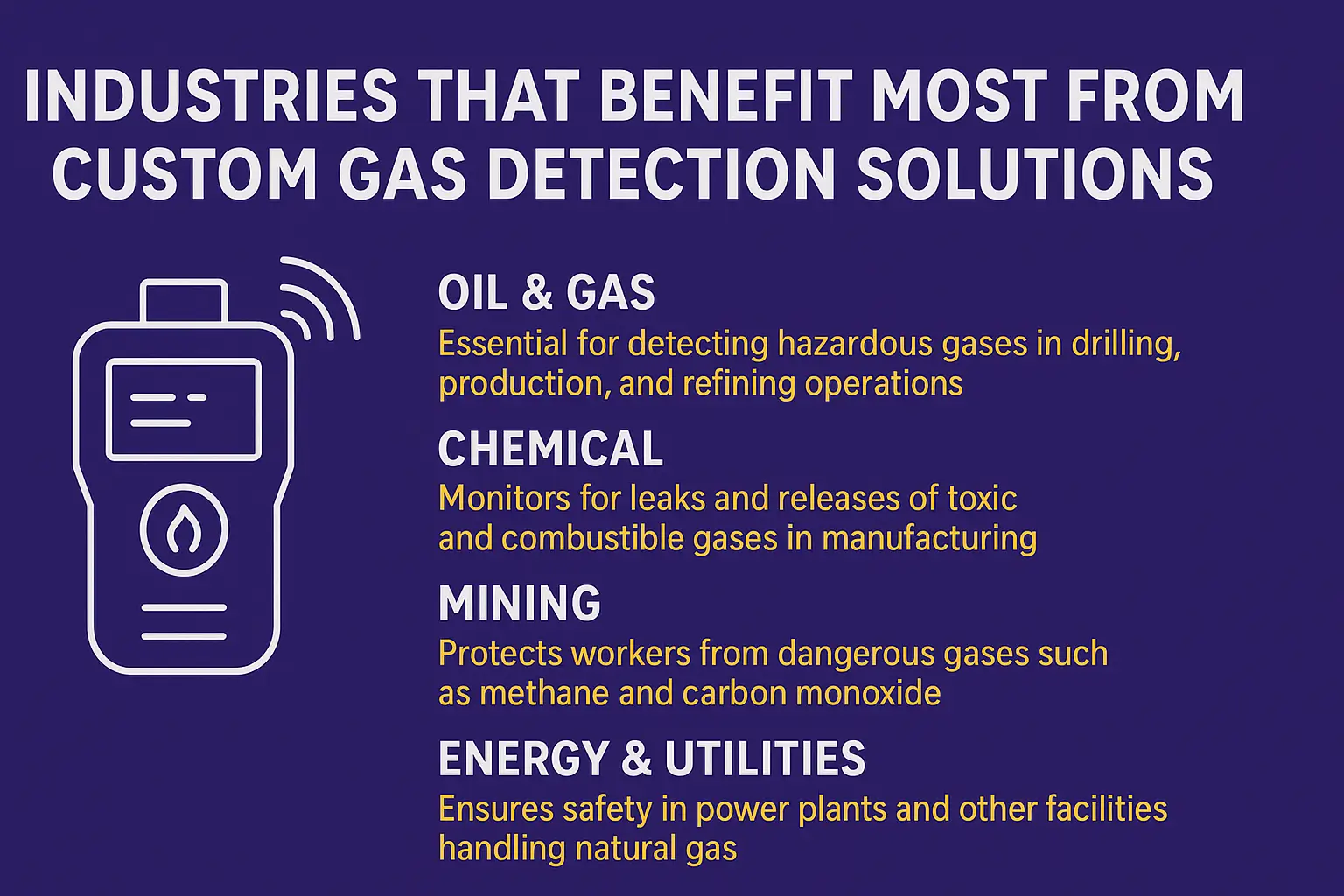

This discussion explores which industries gain the most from tailored gas detection and why businesses are increasingly turning to customised solutions to protect people, assets, and operations.

Why Gas Detection Needs to Be Industry-Specific

Every work environment has its own hazards.

For example, a food processing plant faces very different gas threats compared to an oil refinery, and a mining site will encounter dangers unlike those in a pharmaceutical cleanroom.

Each setting brings its own mix of gases and conditions, so a one-size-fits-all approach will never be enough.

A custom gas detection solution considers the exact gases present, the working environment, sensor placement, and how the system ties into existing processes, ensuring safety with accuracy rather than guesswork.

Safety at the Core of Every Workplace

The importance of gas detection in workplace safety cannot be overstated. Without the right systems in place, even a small leak can escalate into a major incident that threatens lives and disrupts operations.

To understand the true impact of not having effective detection, see why gas detection is so important in workplace safety.

Oil and Gas: Where Safety Margins Are Razor Thin

The oil and gas industry deals with highly flammable and toxic gases daily. Hydrogen sulphide, methane, and volatile organic compounds are constant risks.

Standard detectors may not be sensitive enough or rugged enough for offshore rigs, refineries, or pipelines.

Custom solutions ensure sensors are built for extreme weather, saltwater exposure, and explosive atmospheres.

Key Benefits for Oil & Gas:

- Faster and more reliable detection of toxic and combustible gases, giving workers valuable time to act

- Sensors carefully designed to withstand the punishing conditions of both offshore platforms and onshore facilities

- Seamless integration with emergency shutdown systems so that protective actions are triggered without delay

Chemical Manufacturing: Too Many Gases, Too Little Margin for Error

Chemical plants often handle dozens of different gases within a single facility, each with its own hazards and behaviours.

Trying to manage that variety with a generic detection system is risky, as it simply can’t keep up with the complexity.

Tailored solutions allow for precise detection of multiple gases at different points in the process line. This means early leak detection before small issues spiral into large-scale incidents.

Key Benefits for Chemical Manufacturing:

- Multi-gas monitoring across complex operations, helping plants stay on top of multiple hazards at once

- Lower chance of cross-contamination or false alarms, reducing unnecessary shutdowns and lost productivity

- Stronger compliance with strict safety regulations, giving both management and workers greater peace of mind

Mining: Going Underground with Safety

In underground mining, gases such as methane and carbon monoxide can accumulate quickly in confined spaces, putting workers at serious risk.

Custom-built detection systems are designed to withstand dust, vibration, and humidity, and are positioned to alert miners before conditions become life-threatening.

Key Benefits for Mining:

- Reliable detection even in tough conditions such as dust, high humidity, and constant vibration, where ordinary detectors might fail

- Both portable and fixed solutions available so workers can stay protected whether they are on the move or in one location

- Real-time monitoring that supports clearer evacuation plans and faster decision-making in emergencies

Food and Beverage: Safety Beyond the Kitchen

It may come as a surprise, but the food and beverage industry also faces gas hazards.

Ammonia in refrigeration and carbon dioxide in beverage production both require customised detection to keep workers safe and prevent costly shutdowns.

Key Benefits for Food & Beverage:

- Careful monitoring of ammonia and CO2 levels to prevent leaks from becoming dangerous incidents

- Stronger protection for workers who spend time in confined storage rooms and processing spaces where gases can build up quickly

- Reduced product spoilage and downtime, helping operations stay safe while keeping production on track

Pharmaceuticals: Protecting Both Workers and Products

In pharmaceutical manufacturing, precision is everything. The presence of even small leaks of solvents or gases can compromise product integrity.

Custom detection systems provide high sensitivity and integration with cleanroom requirements.

Key Benefits for Pharmaceuticals:

- Ultra-sensitive detection for solvents and volatile compounds

- Compliance with strict GMP (Good Manufacturing Practice) standards

- Safeguarding both employees and high-value products

Power Generation: Keeping Operations Running Safely

Power plants, especially those using coal or natural gas, produce emissions that require careful monitoring.

Custom solutions provide early warnings for leaks and enable compliance with environmental regulations.

Key Benefits for Power Generation:

- Monitoring of carbon monoxide, SO2, and NOx gases

- Integration with control systems for automatic shutdowns

- Protecting both workers and communities

Waste Management: Hidden Hazards in Everyday Operations

Waste collection, recycling, and landfill operations can expose workers to gases like methane, hydrogen sulphide, and volatile organic compounds.

These gases often accumulate unnoticed, making tailored detection essential for both safety and environmental protection.

Key Benefits for Waste Management:

- Detection of methane build-up in landfills to reduce fire and explosion risk

- Continuous monitoring of hydrogen sulphide during waste treatment processes

- Improved worker safety during collection, sorting, and recycling activities

Beyond Compliance: The Role of Regulations and Standards

Regulatory bodies across the globe set strict rules for gas monitoring in industries where safety and environmental impact are at stake.

Meeting these standards isn’t just about avoiding fines; it’s about proving commitment to protecting workers and surrounding communities.

Custom solutions make compliance easier by aligning detection systems with both local and international requirements, reducing risk of violations while building trust with stakeholders.

For a closer look at how tailored systems can be designed for your workplace, see our Minerva’s Custom Gas Detection Solutions page.

Maintenance Matters: Going Beyond Installation

Installing a custom gas detection system is only the first step. Keeping it reliable means regular checks, timely calibration, and predictive upkeep that prevents issues before they cause downtime.

Companies that adopt smarter maintenance approaches gain longer system life and greater peace of mind.

Learn more about why traditional checks aren’t enough in our guide on Implementing Predictive Maintenance for Gas Detectors.

Why Choose Minerva

Minerva Intra is not just another gas detection provider. With decades of expertise in industrial safety, we design solutions that match the exact needs of each client.

From system design and installation to training and after-sales support, our approach ensures reliability and compliance at every step.

Whether your business operates in oil and gas, food production, or wastewater treatment, Minerva creates customised gas detection systems that put safety first without compromising efficiency.

Take the Next Step

Don’t wait until an incident proves that your detection system isn’t enough.

Contact Minerva Intra today to explore how a custom gas detection solution can transform safety in your workplace.

Book a consultation with our team of experts and take control of your safety strategy.