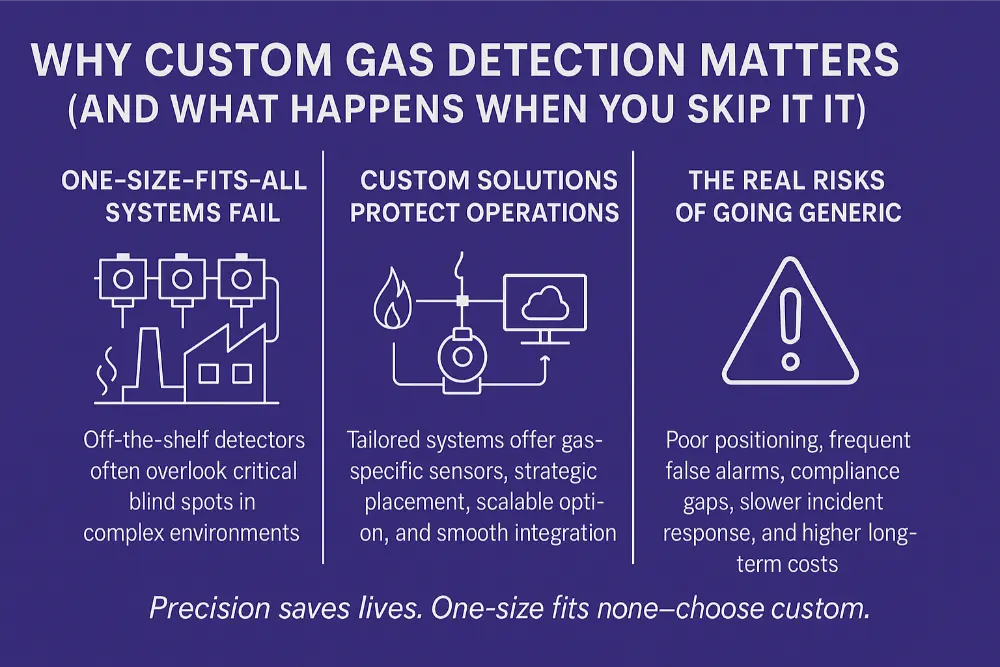

TL;DR: Standard gas detectors can miss serious risks in complex or high-risk workplaces where conditions fall outside the norm. Custom gas detection systems are a smarter choice: they offer greater accuracy, better alignment with compliance requirements, and more reliable protection for both workers and the facility.

Key Takeaways:

- Standard gas detectors aren’t always suited for specialised or high-risk environments

- Custom solutions offer better accuracy, fewer false alarms and seamless system integration

- Compliance requirements in some industries demand tailored gas monitoring setups

- Investing in a custom solution helps avoid fines, downtime and safety incidents

When it comes to safety in industrial settings, gas detection is often treated as something routine, just a box to tick.

Many businesses install standard gas detectors and then assume the job is done. But the truth is, not every workplace fits the usual mold.

If your environment has unique risks or operates differently from the norm, relying on generic gas detectors might leave you vulnerable to dangers you can’t even see.

This could mean missing hazardous gas leaks, running into trouble with safety regulations, or worse, putting your workers in harm’s way.

So, when do you need custom gas detection? The answer might be sooner than you realise. There are clear signs that your business might benefit from a more customised solution.

In many cases, custom gas detection isn’t just a nice-to-have; it’s a crucial part of keeping your team safe and staying compliant with safety regulations.

Why Standard Gas Detectors Might Not Cut It for Your Business

The Limitations of Off-the-Shelf Gas Detection

Generic gas detectors are designed to cover common scenarios, such as detecting basic gases like carbon monoxide or methane in typical environments.

These solutions work well for many businesses with straightforward monitoring needs.

However, if your facility handles specialised chemicals, operates in extreme environments, or faces complex safety requirements, standard detectors may fall short.

For example, if you deal with toxic or combustible gases unique to your operations, standard sensors might not detect them accurately or quickly enough. Here’s a quick guide to how gas detectors actually work if you need a refresher.

The Hidden Risks of Using Generic Solutions

Picking the wrong gas detection system can turn into a major headache.

One minute your operations hum along, the next you’re scrambling to deal with false alarms that bring everything to a standstill, or worse, you don’t even see the real leak sneaking up on you.

When readings are slow or off the mark, your team’s safety is at stake and unexpected downtime can blow out your budget before you know it.

On top of that, regulators keep tightening the screws on safety standards. They expect your monitoring gear to match the exact hazards on site, and generic detectors rarely fit the bill.

If your equipment isn’t up to the task, you risk:

- Failing compliance checks

- Receiving hefty fines

- Getting hit with shutdown notices

These are outcomes no business can afford to ignore.

How to Tell If Your Business Actually Needs Custom Gas Detection

Why Your Environment Demands a Tailored Gas Detection Approach

Every industrial site is different. How well a gas detector performs depends on several key factors:

- Types of gases you handle

- Layout and size of your facility

- Environmental conditions such as humidity, temperature and airflow

If your site deals with rare gases or faces challenging conditions such as confined spaces, outdoor exposure to weather elements, or areas with fluctuating temperatures, custom sensors built for those exact circumstances will offer more reliable protection.

Evaluating Your Operational Challenges

Complex manufacturing and processing plants usually face several layers of risk.

You might be working with multiple gas sources, unusual mixtures, or setups that make it hard to get complete coverage.

Standard detectors often struggle to connect with older systems or to pull everything into a single dashboard.

This is where a custom solution makes a real difference.

It can be built to fit your setup exactly, link with your current safety systems, and give you centralised monitoring that makes it easier to catch problems early and respond faster when something goes wrong.

When Regulations Demand More Than the Basics

Some industries face strict safety regulations that go beyond generic requirements:

- Petrochemicals, pharmaceuticals and food processing often require equipment certified to higher standards

- Monitoring of specific hazardous gases may be legally mandated

- Non-compliance can lead to hefty penalties and shutdowns

In these environments, investing in customised gas detection is essential to meet compliance and avoid costly fines or interruptions.

Custom Gas Detection: What Makes It Different and Worth It?

Tailored Sensors for Your Specific Gases and Conditions

Custom gas detectors are built with your unique gases and environment in mind.

Whether you need to monitor rare chemicals or a mixture of gases, custom sensors are designed to detect these accurately, avoiding gaps in safety coverage.

Learn more about the advantages of custom gas detection systems and why they offer better protection compared to off-the-shelf options.

Enhanced Accuracy and Reliability

False alarms waste time and money. Custom gas detection systems improve accuracy by tuning sensor sensitivity to your specific needs.

This reduces false positives and ensures stable performance even in difficult environments. Benefits include:

- Fewer false alarms that interrupt operations

- Better performance in harsh or variable conditions

- Lower risk of missing a real leak or event

- Less downtime and more efficient workflows

- Safer conditions for staff working near potential hazards

Seamless Integration and Future-Proofing Your Safety Setup

A custom system can be designed to work with your current safety infrastructure, including alarms and control rooms, as well as remote monitoring systems.

This integration improves response times and helps you scale or upgrade your safety systems easily over time.

Why Choose Minerva Intra for Your Custom Gas Detection Needs

Minerva Intra has worked with Singapore’s most demanding industries for decades. We don’t just supply equipment.

We stay involved from assessment through support to make sure your gas detection setup matches how your site operates. As your needs change, we adapt with you.

Our technology is made for real-world use, not just ideal conditions.

Whether you’re monitoring toxic gases, flame risks or environmental exposure, our systems are trusted across pharma, petrochemical and food sectors for accuracy and reliability.

Explore our gas flame detection and environmental monitoring solutions to see how we help businesses like yours stay protected around the clock.

Take Control of Your Business Safety Today

Don’t wait for a gas leak or regulatory warning to realise your detection system isn’t enough.

With customised gas detection from Minerva Intra, you can safeguard your people, protect your operations and stay compliant with ease.

Contact Minerva Intra today for a free consultation. Let us take the first step towards smarter, safer operations.