TL;DR: Failing to calibrate gas detectors leads to inaccurate readings, safety risks, and potential legal trouble. Regular calibration keeps your detectors reliable and your workplace safe.

Key Takeaways:

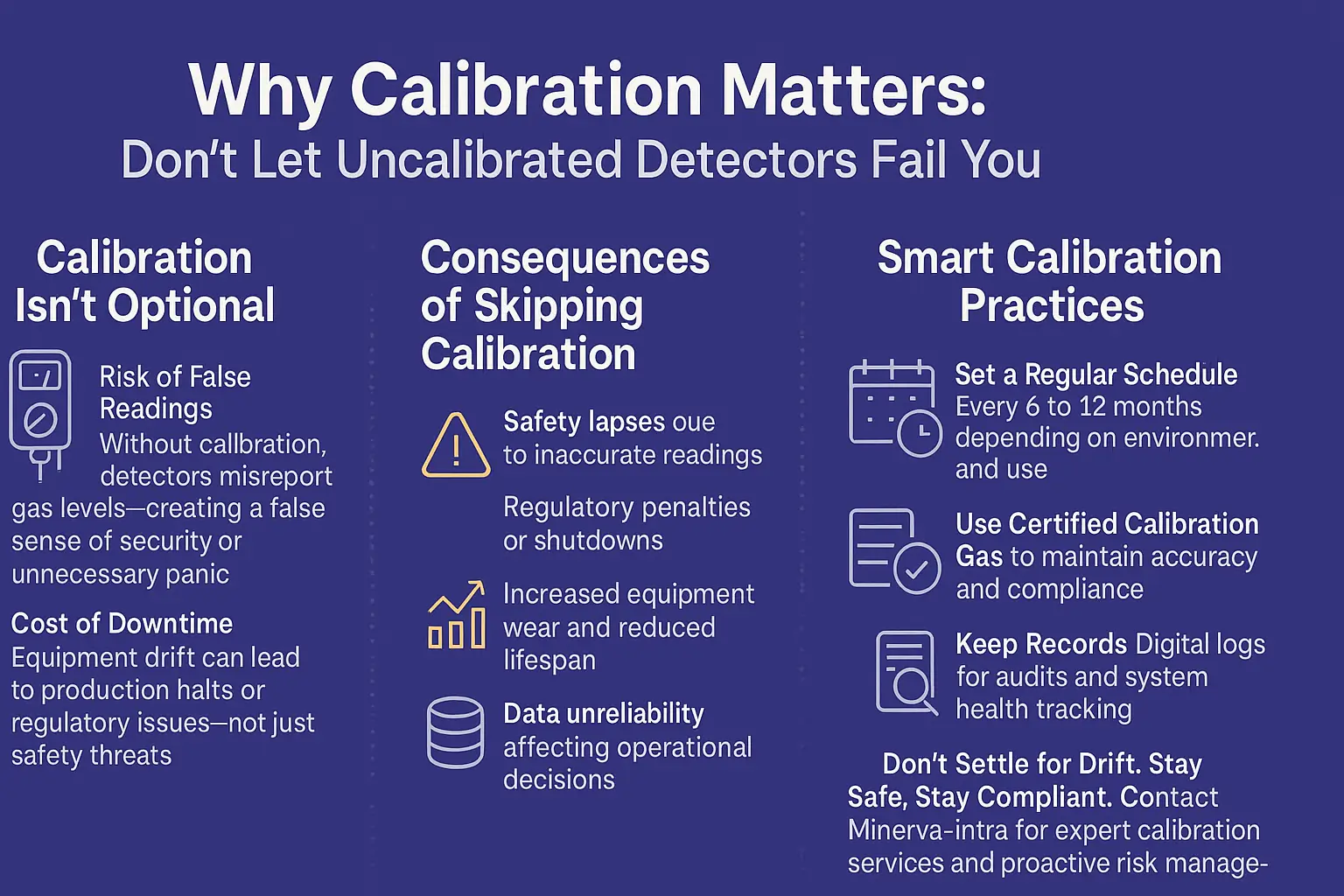

- Uncalibrated gas detectors can give false readings, putting workers and operations at risk.

- Regulations require regular calibration to avoid legal and financial consequences.

- Environmental stress and daily use cause sensor drift, especially in Southeast Asia.

- A proper maintenance routine helps ensure safety and consistent performance.

Gas detectors play a quiet but essential role in keeping people safe in high-risk environments.

From oil rigs and chemical processing plants to underground tunnels and manufacturing floors, these devices alert teams to dangerous gas levels before things go wrong.

But here’s the catch: they can only do their job if they’re properly maintained.

One key step that often slips through the cracks is regular calibration. It might seem like a small thing, but it’s the difference between a detector that saves lives and one that gives a false sense of safety.

Skipping it isn’t just poor maintenance. It’s a serious risk that can endanger lives and put your entire operation in jeopardy.

What Happens When You Skip Calibration?

False Sense of Security

Gas detectors that aren’t calibrated as they should be might still light up, beep, and display numbers, giving workers the impression that everything is under control. But those signals can be misleading.

Without proper calibration, readings can drift significantly over time. That can lead to misreads, which in turn cause:

- Failure to detect rising gas levels when they actually pose a serious threat to workers on-site.

- False alarms that disrupt operations, waste time, and cause unnecessary panic.

In both cases, the result is confusion, missed warnings, and added risk.

Dangerous gases might be building up quietly while the detector continues to show a green light, leaving everyone exposed and unaware of the danger.

Compliance Risks and Legal Fallout

Workplace safety regulations, including those from OSHA (Occupational Safety and Health Administration) in the United States and other authorities across Southeast Asia, usually call for routine calibration as part of safety protocols.

Ignoring this requirement doesn’t just risk a slap on the wrist. It can lead to costly fines, forced shutdowns, or even legal action if something goes wrong.

Financial Consequences

When gas detectors aren’t calibrated properly, the fallout can be more than just a safety concern.

Inaccurate readings often lead to operational disruptions; whether it’s false alarms causing production delays or undetected gas leaks that escalate into serious incidents.

Both situations have one thing in common: they cost money. Unnecessary shutdowns, emergency response measures, equipment damage, and regulatory fines can quickly add up.

Beyond the immediate expenses, there’s the longer-term cost of lost productivity, missed deadlines, and damaged trust within the team and with clients..

Why Gas Detection Equipment Drifts Over Time

Environmental Conditions

Environmental factors like humidity, dust, and temperature shifts all take a toll on gas sensors.

These issues aren’t rare or occasional; they’re part of the everyday reality in many Southeast Asian worksites.

In places like Singapore, it’s common to deal with:

- High humidity, which can gradually impact the chemical stability inside sensors.

- Airborne dust, which may clog or coat sensor surfaces and reduce accuracy.

- Frequent temperature changes, which can throw off sensor readings and response times.

Over time, exposure to these conditions reduces the reliability of detectors.

That’s why regular calibration isn’t optional; it’s necessary for keeping equipment dependable when it counts.

If you’re unsure how gas detectors actually work or what goes into their design, you can learn more about how gas detectors function here.

Sensor Degradation

Just like any piece of equipment, gas sensors wear down over time. The more they’re used, the more their accuracy can fade.

This is especially true for electrochemical sensors, which are commonly used to detect toxic gases.

These types tend to lose sensitivity faster, which is why they need to be checked and recalibrated more often to stay reliable.

Regular Usage

When gas detectors are regularly exposed to different gases, their sensors slowly start to drift from their original calibration.

Over time, this exposure affects how accurately they respond to gas levels.

Detectors used in busy or high-risk environments tend to drift faster, which means they need to be calibrated more frequently to stay reliable and effective.

How Often Should You Calibrate Your Gas Detectors?

There’s no single rule for how often you should calibrate gas detectors, but having a clear and consistent routine makes all the difference. In most cases:

- A daily bump test is a quick check to confirm your detectors are responsive and can still pick up the presence of gas.

- Monthly calibration helps bring the sensors back to accurate levels, especially in environments where they’re used often.

- If a detector goes off or there’s known exposure to gas, it’s best to recalibrate it right away to make sure it’s still reliable.

- And finally, always follow the manufacturer’s recommendations, which are based on the specific design and performance patterns of each device.

Sticking to these habits can help your detectors stay dependable when it matters most.

The Smart Way to Handle Calibration

Implement a Calibration Schedule

It’s easy to lose track of maintenance if you’re relying on memory or informal routines. Set a clear, written schedule for every gas detector you use.

Use software or maintenance logs to keep things consistent, and make sure everyone knows what’s due and when.

Train Staff Properly

Your team needs more than just a general idea of how to run a bump test. Make sure your safety and operations staff understand the right steps and why each one matters.

A bit of proper training can go a long way in keeping things safe and accurate.

Use Certified Calibration Gas

Always use calibration gas that matches the specific type and concentration required for your detectors.

Using the wrong gas, or making assumptions, can throw off your readings and make the whole calibration pointless.

It’s a simple step, but getting it wrong can lead to serious consequences down the line.

If you’re working in a specialised environment or have unique operational needs, off-the-shelf solutions may not be enough.

Custom gas detection systems can offer better coverage, improved efficiency, and more reliable safety outcomes. You can read more about the advantages of custom gas detection systems here.

Why Choose Minerva?

At Minerva Intra, we understand that reliability isn’t optional when it comes to gas detection.

That’s why we provide trusted calibration services that are fast, accurate, and backed by deep industry knowledge.

We don’t just sell equipment. We partner with you to maintain it.

To explore our full range of safety solutions and see how we support industries across Southeast Asia with reliable gas detection systems, visit the Minerva Intra homepage.

You’ll find detailed insights on our services, calibration support, and equipment designed to keep your operations safe and compliant.

Let our trained technicians help you avoid the risks and the costly consequences of uncalibrated gas detectors.

Talk to the Experts Today

Calibration isn’t just a technical maintenance task. It’s a core part of your safety system.

If your team relies on gas detection, don’t wait until a false alarm or a missed one causes a real problem.

Your safety, compliance, and peace of mind are worth it.