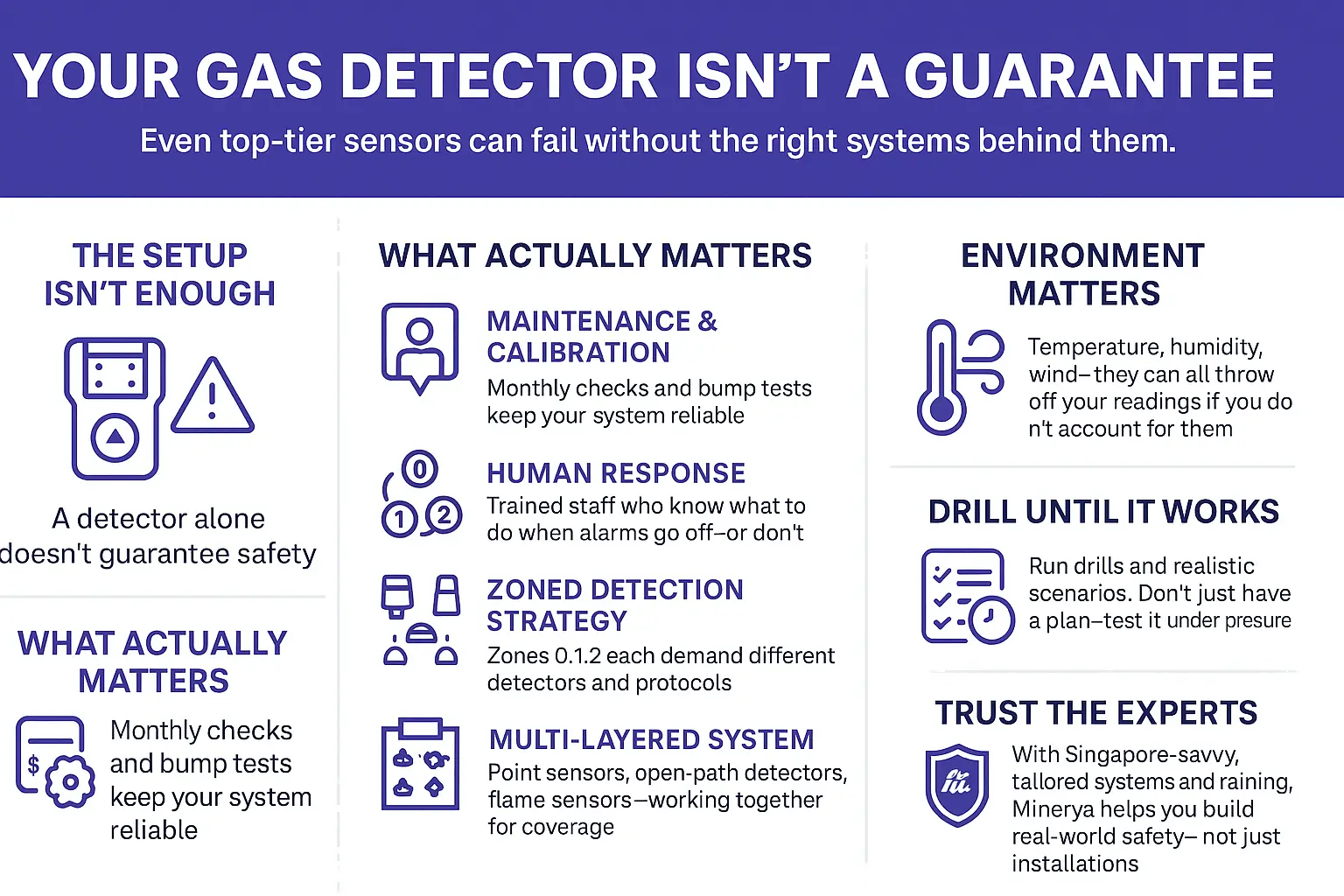

TL;DR: Installing a gas detector isn’t enough to ensure safety in hazardous areas. Without proper maintenance, staff training, multi-layered detection systems, and real-world emergency drills, even the best sensors can fail. Safety depends just as much on human response and planning as it does on the equipment itself.

Key Takeaways:

- Gas detectors need regular maintenance and calibration to stay reliable.

- Human error remains a major risk without clear roles, training, and drills.

- A multi-layered detection system improves reliability and reduces false alarms.

- Environmental conditions can impact sensor accuracy if not properly considered.

Why Gas Detection Isn’t Just “Set and Forget”

Many businesses think that once a gas detector is installed, the job is done. But the truth is, a sensor can’t do much on its own without a well-thought-out plan to support it.

That plan needs to include what happens before, during, and after the detector picks up a threat.

Working in hazardous zones takes more than just gear and good intentions.

It calls for a clear system, consistent drills, and people who are trained to act fast when an alarm goes off, or when it fails to go off entirely.

Understanding the Risk Zones: Not All Areas Are Equal

Some areas are more prone to explosive or toxic gas exposure than others. These are classified into three main zones based on how often and how long gas is expected to be present:

- Zone 0: Gas is present all the time or for long periods under normal conditions.

- Zone 1: Gas may be present during normal operations, but not continuously.

- Zone 2: Gas is only likely to be present in abnormal situations, such as during equipment failure or leaks.

Each zone requires its own set of safety procedures, detector types, and maintenance routines.

Knowing how your site is zoned helps ensure you’re choosing the right tools and creating procedures that match the actual level of risk in each space.

The Most Common (and Dangerous) Mistake: Poor Maintenance

It’s surprising how often gas detectors are left running until something goes wrong.

Without regular calibration or even basic bump tests, even the most dependable units can give false readings or fail completely just when they’re needed most.

Maintenance should never be an afterthought. It’s a vital part of keeping the system reliable.

Monthly checks can catch problems early and give your team the peace of mind that the alarms will work when it really counts.

Without regular calibration or even basic bump tests, even the most dependable units can give false readings or fail completely just when they’re needed most.

Learn why this matters in our article on why skipping custom gas detection leaves your business one leak away from disaster.

Real-World Oversight: Human Error Is Still the Biggest Threat

Even with the best technology in place, people still make the final decisions and mistakes.

When detectors are muted during inspections or installed in the wrong spots, the whole system can break down.

To reduce the risk of human error, teams need:

- Clear understanding of gas readings so workers know what the numbers mean and can make informed decisions on the spot, instead of hesitating or second-guessing.

- Prompt response habits so staff don’t freeze up or waste time figuring out what to do when an alarm sounds. Every second counts.

- Familiarity with emergency exits and routes so evacuation is instinctive, not something that needs to be figured out in the moment.

- Regular hands-on training that lets workers practise real scenarios and build confidence, making them more likely to respond the right way under pressure.

These aren’t extras or optional upgrades. They’re the basics that make sure your team stays safe when a real emergency hits.

What Happens Next Matters More

Detection is just the beginning. What matters just as much is how your team responds after a gas leak is detected.

Your safety protocols should clearly outline who takes action, what steps they follow, where they need to go, how they communicate with others, and who is responsible for shutting down equipment or operations.

A strong emergency response plan is built to remove any guesswork during a crisis. Everyone on-site should know exactly what to do without second-guessing.

This kind of clarity only comes from regular training and practice.

Choosing how your team responds is just as important as what technology you install.

Learn more about the gas detection decision that could save your site and how smart planning can make all the difference.

Multi-Layered Protection: One Alarm Isn’t Enough

A strong gas detection system doesn’t rely on just one sensor.

Instead, it uses a multi-layered approach, where different types of detectors work together to cover more ground and catch more threats.

This might include:

- Point detectors to monitor specific spots where leaks are most likely

- Open-path detectors to scan wider areas between two points

- Flame sensors to detect fires or explosions caused by gas leaks

By combining these layers, the system becomes more reliable.

If one sensor misses something, another one can still catch it. This setup helps cut down false alarms and gives your team more time to respond.

Explore how we use these technologies together on our Gas, Flame Detection & Environment Monitoring page.

Environmental Conditions Can Mess With Your Readings

Temperature, humidity, wind, and pressure can all interfere with how well a gas detector works.

If a sensor is placed in the wrong environment or isn’t designed for the conditions, it may give inaccurate readings or not work at all.

This is why selecting the right sensor goes beyond technical specs because it depends on where and how it will be used.

Getting advice from someone who understands both the technology and your site conditions can make a big difference in how safe your setup really is.

Are You Testing or Just Hoping?

When was the last time you actually put your gas detection plan to the test?

Not in theory or a checklist, but through a real-world exercise where people had to move, react, and communicate under pressure.

Having a plan is one thing but knowing it actually works is another.

Simple actions like running tabletop drills, creating realistic leak scenarios, or setting off live alarms can expose weak spots you didn’t know existed.

These activities might feel repetitive, but they prepare your team to act with confidence when it’s no longer a drill.

The Cost of Complacency Is Higher Than You Think

When gas detection systems fail, the consequences can pile up quickly. We’re talking about unexpected downtime, injured workers, legal trouble, and a serious hit to your company’s reputation.

And more often than not, it all starts with something simple being overlooked. It could be skipping regular checks or trusting that the system will always work as expected.

At the time, it might not feel like a big deal, but these small lapses can quickly lead to dangerous situations.

Why Partnering With the Right Expert Changes Everything

Minerva Intra is trusted across Southeast Asia for good reason.

We work closely with you to build proper procedures, train your staff effectively, and ensure your safety layers stay reliable and ready at all times.

We’ve supported oil & gas, chemical, marine, and other high-risk sectors with fit-for-purpose gas detection solutions that don’t just check boxes; they save lives.

We bring practical experience and tailored solutions that help keep your site safe and your operations running smoothly.

Let’s Make Sure Your Site Isn’t the Next Headline

Get in touch with Minerva Intra to review your current gas detection setup and identify where improvements can be made.

Whether you’re looking to upgrade your equipment, improve staff readiness, or build a safety protocol from the ground up, our team is here to guide you every step of the way.